The HQ series pumps are designed for water supply and pressure boosting in residential, commercial and light industrial applications where low or inadequate water pressure exists. It is suitable for boosting pressure from underground or surface water supplies.

All-in-one unit consisting of pump, motor, pressure vessel and electronic controller. This ensures that the pump starts automatically when water is required and operates continuously until it is not.

Anti-cycling feature that prevents the pump from continuous starting and stopping due to a minor leak in the system

Built-in dry-run shut off with automatic reset function.

Designed for water supply and pressure boosting in residential and commercial applications where low or insufficient water pressure exists.

The new feature of the HQ_B series includes adding silver ions to the pump casing. Scientifically proven to inhibit microbial growth by 99% over a 24-hour period.

Potable water or other clean, thin or non-aggressive liquids

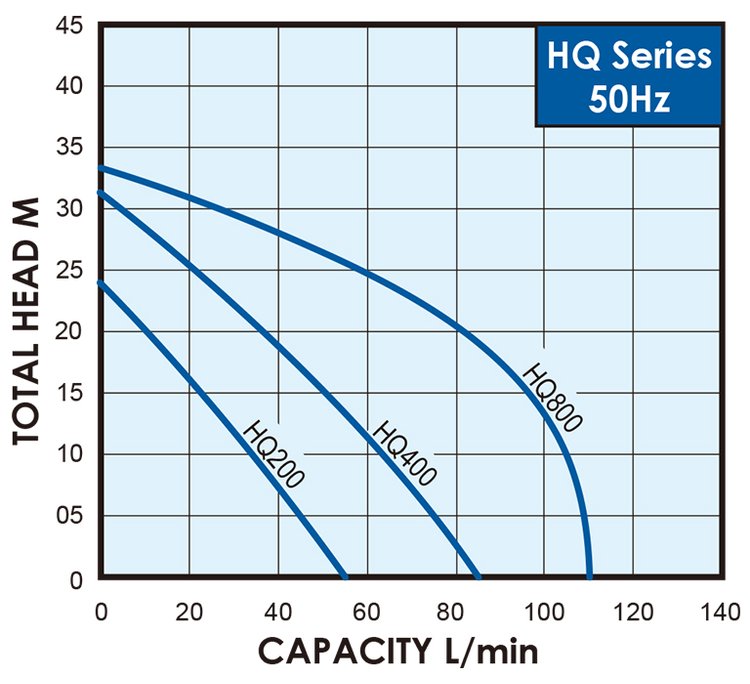

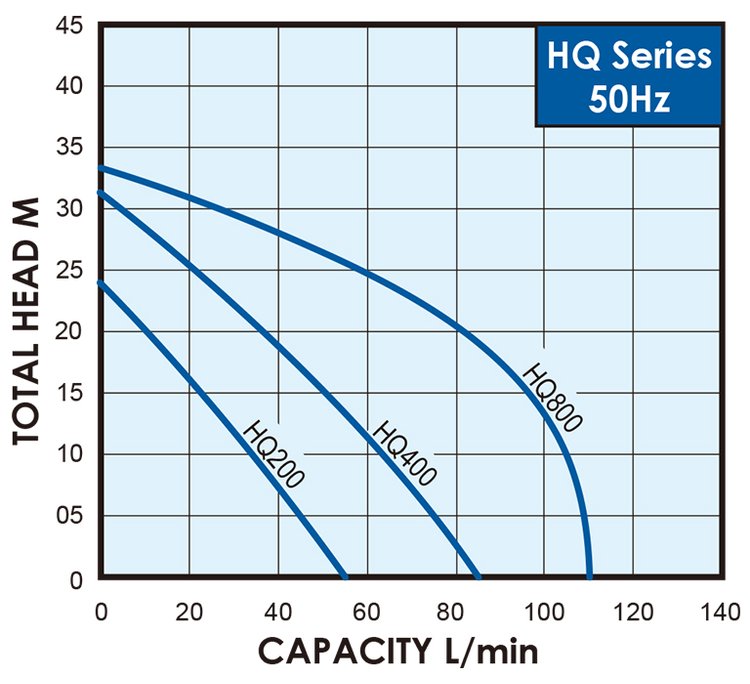

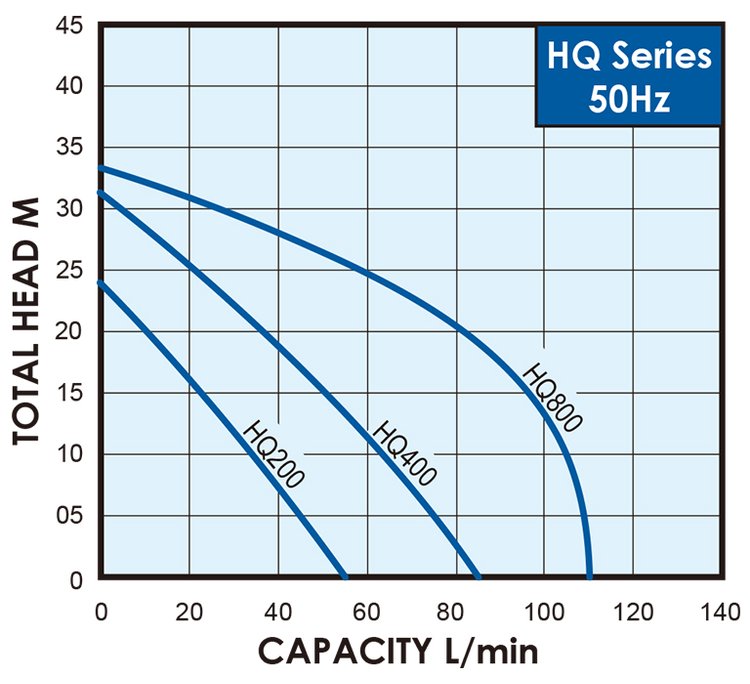

| HQ 200 |

| Power KW |

Voltage V |

Preset Activation kg/cm2 |

Inlet in. |

|---|---|---|---|

| 0.18 | 230 | 1.6 | 1" |

| Outlet in. |

Flow Rate L/min |

Head M |

N.W kg |

|---|---|---|---|

| 1" | 55 | 24 | 7.5 |

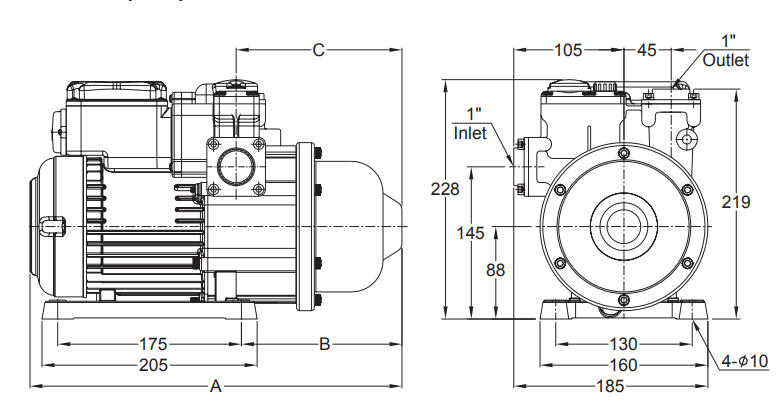

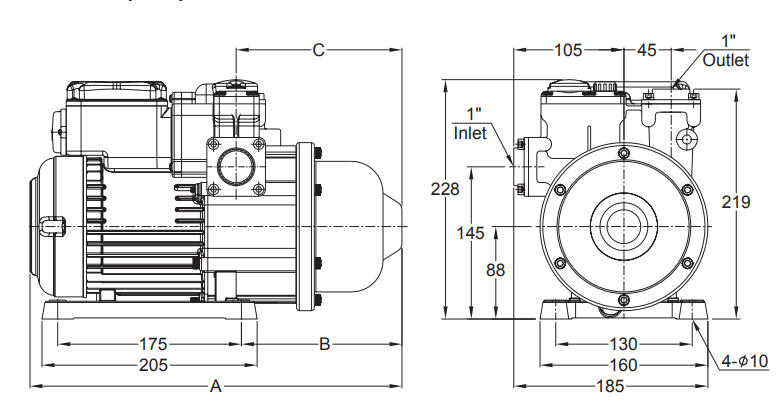

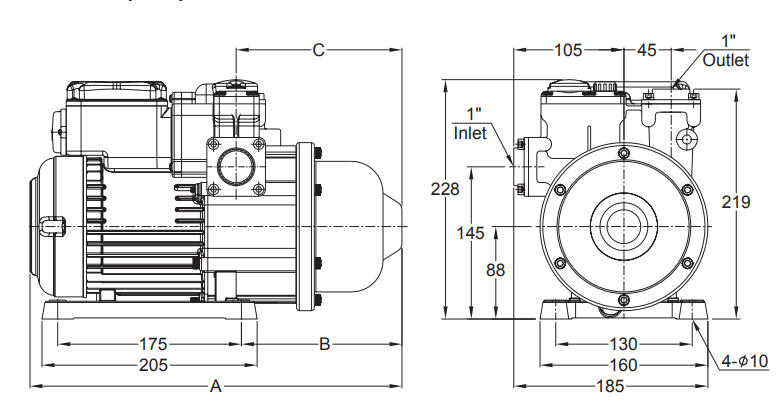

| Cycle (Hz) | A | B | B | N.W. (kg) |

| 50 | 355 | 153 | 158 | 7.5 |

| HQ 400 |

| Power KW |

Voltage V |

Preset Activation kg/cm2 |

Inlet in. |

|---|---|---|---|

| 0.37 | 230 | 2 | 1" |

| Outlet in. |

Flow Rate L/min |

Head M |

N.W kg |

|---|---|---|---|

| 1" | 85 | 31 | 8.5 |

| Cycle (Hz) | A | B | B | N.W. (kg) |

| 50 | 355 | 153 | 158 | 8.5 |

| HQ 800 |

| Power KW |

Voltage V |

Preset Activation kg/cm2 |

Inlet in. |

|---|---|---|---|

| 0.75 | 230 | 2 | 1" |

| Outlet in. |

Flow Rate L/min |

Head M |

N.W kg |

|---|---|---|---|

| 1" | 110 | 33 | 11.3 |

| Cycle (Hz) | A | B | B | N.W. (kg) |

| 50 | 410 | 162 | 167 | 11.3 |

The HQ has the built-in pressure switch and internal flow switch. Each of these can turn the pump on depending on water consumption. The pump will start when:

- The pressure is BELOW the pressure switch activation point. OR

- The flow rate is greater than 3.0-3.5 lpm.

The preset activation point for each model is provided in the pump specifications. The cut in pressure must be lower than the preset activation pump; otherwise the pump will not start.

Adjust the pressure only when the cut in pressure is higher than the preset activation point. Do not adjust the pressure to exceed the maximum pressure range as below because too high pressure may cause the pump not stop.

1. The flow switch is designed to automatically stop the pump when water flow drops below 3.0-3.5L/min

2. Pump will shut off in a few seconds after flow stops (It is programmed to stop after 6 seconds). To avoid dry run without liquids, It will automatically stop after 1 minute. Pump will automatically rest for 10 minutes and restart again. If above cycling happened accumulate 3 times, the rest time will become 1 hour and restart again. If the water is enough for pump to restart during the 1 hour rest time, it will automatically start again after the rest time. For immediately start the pump, please turn the power off for at least 6 seconds and turn on again.

3. Water temperature protection will activate when it is over 50℃, and pump will automatically stop. It will reactivate when temperature drops to 35℃.

4. Motor protection for HQ200 and HQ400 will activate when temperature is over 130℃. Motor protection for HQ800 will activate when temperature is over 150℃. Pump will automatically stop.

The pressure tank comes from the factory pressurized at approximately 1.0 - 2.5 kg/cm² (with the pump pressure at zero). It is designed to minimize motor startup due to small flow demand or minor leak of the pipeline.